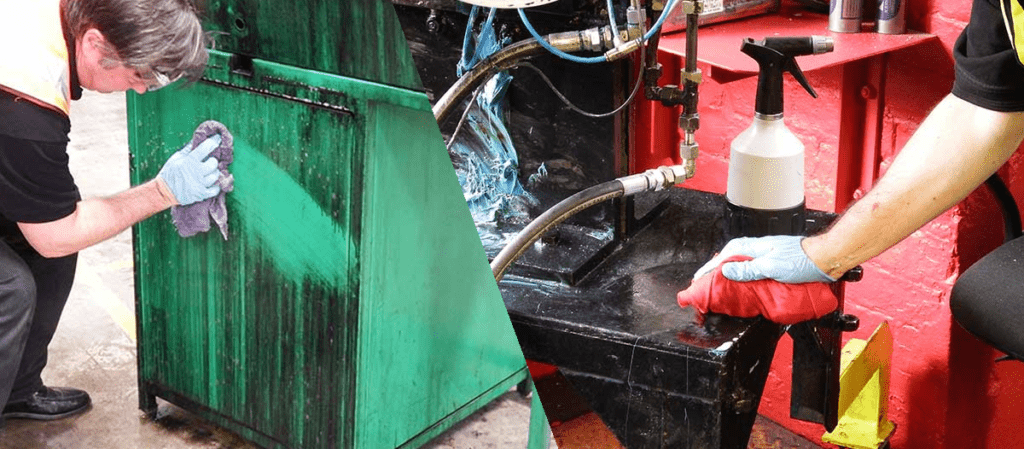

Best Hot Melt Glue Dispensing Equipment for Smooth Production While unplanned downtime has always been a huge thorn in any manufacturer’s side, it doesn’t have to spell doom for your business. With the right hot melt glue dispensing equipment, the … Read More